Iterative prototype

development & scalable

series production

Case Study Plant Engineering

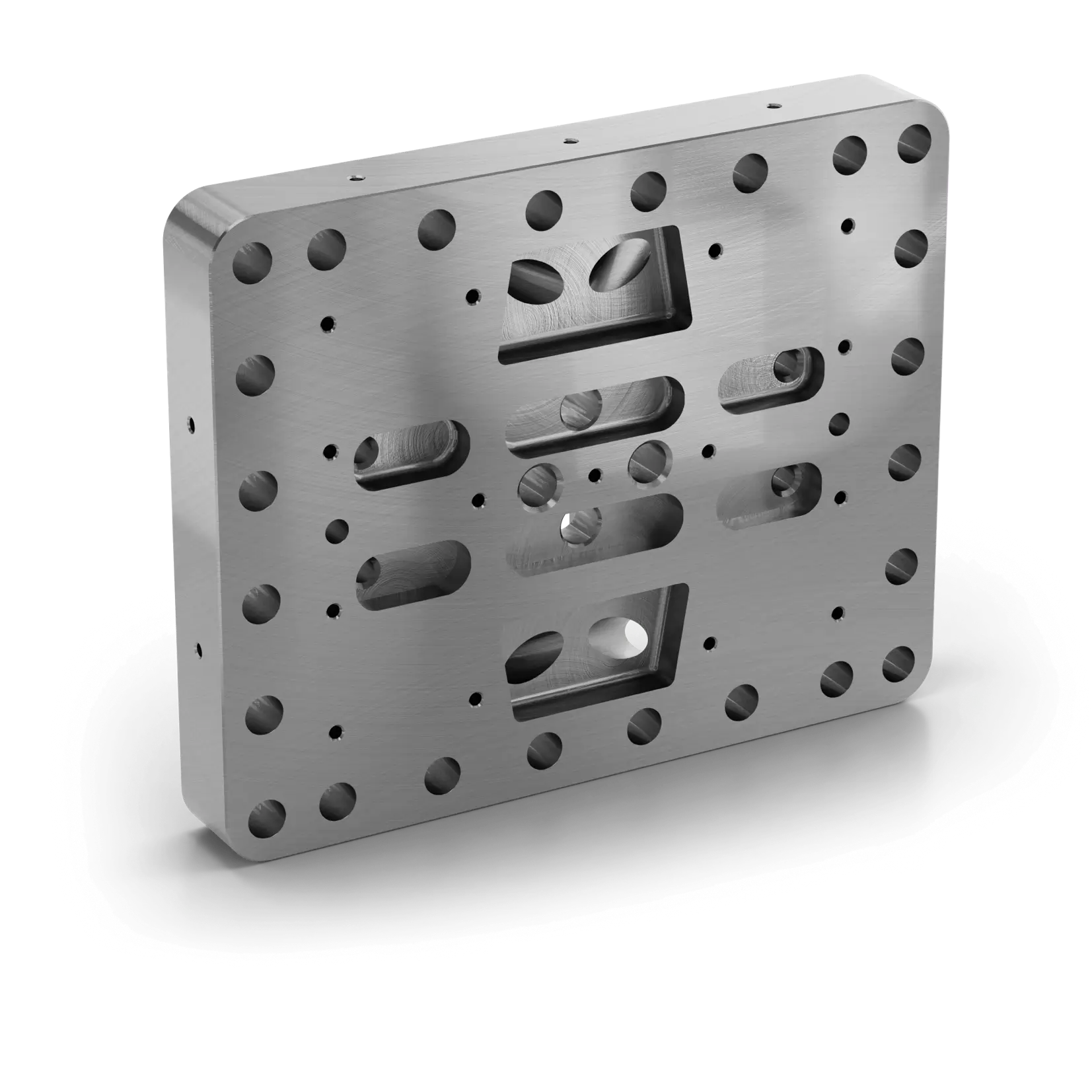

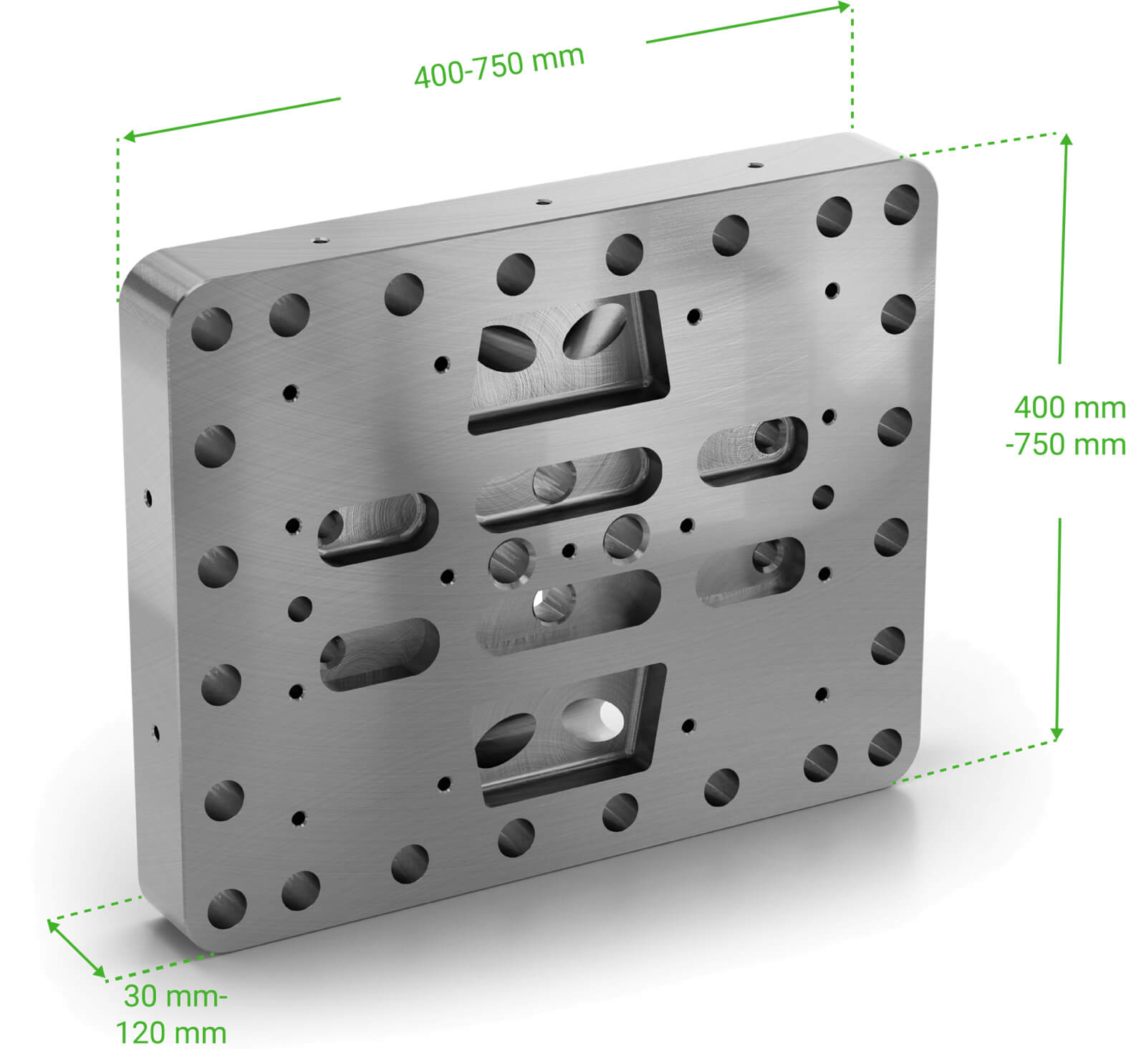

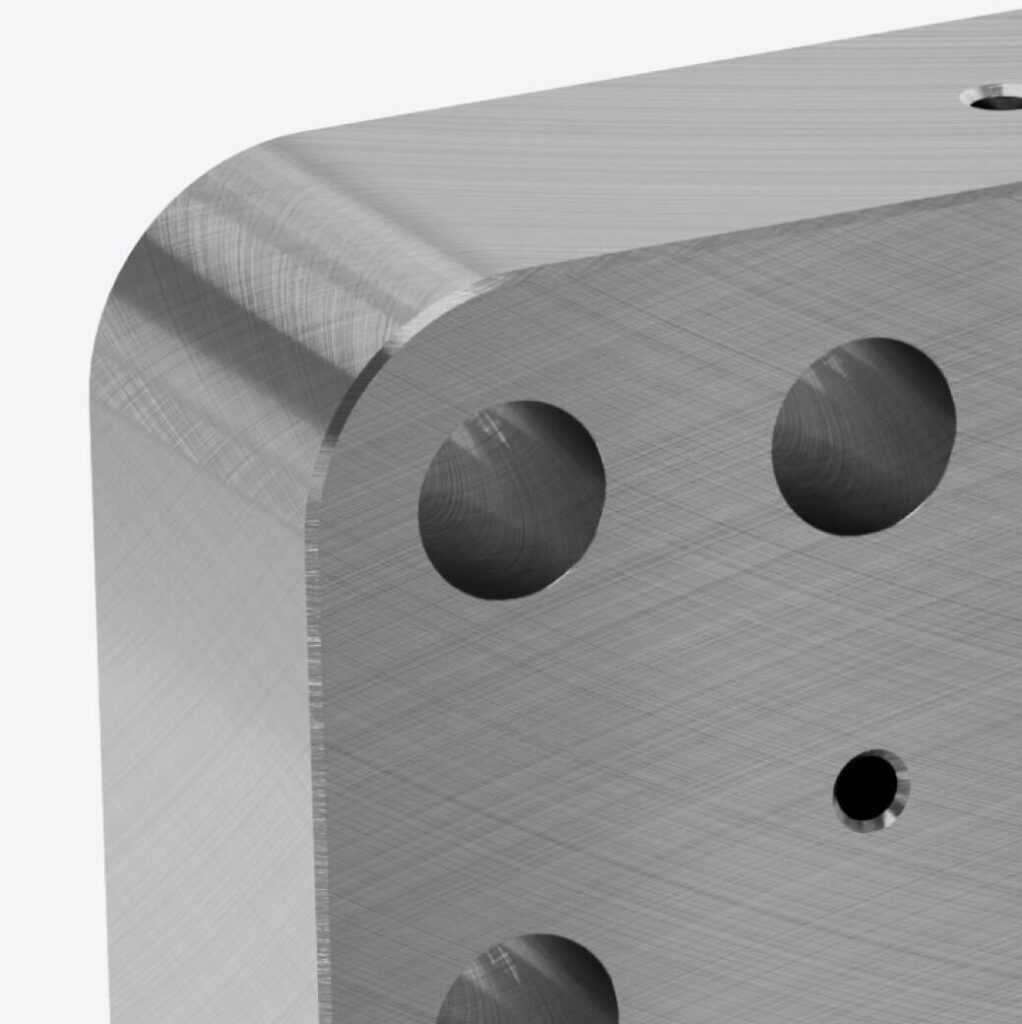

Custom-milled stainless steel part, used in plant engineering for hydrogen production

Milled Part Drawing part

Task: Manufacturing an extremely precise, angular stainless steel milled part for hydrogen production plant engineering – realized in a short time and scalable for multiple variants.

Solution: Special stainless steel milled part manufactured with optimized clamping technology, scaled from pilot series to a complete product family – with maximum precision, high repeatability, and perfect integration into series production.

Dimension | Material & Hardness | Tolerances & Quality |

|

|

|

Milled Part Drawing part

Challenge

Make technically complex custom manufacturing ready for series production in record time

HSP supported a globally operating company in the field of hydrogen technology and plant engineering for the energy industry in making a custom component ready for series production. The component was theoretically and constructively designed by the customer as part of a new development. In close

collaboration with the customer, the complex component was to be brought from prototype to series production readiness within the shortest possible time.

Special technical challenges:

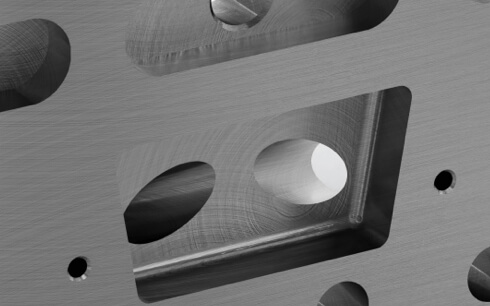

- Complex, angular geometry with tight form and position tolerances

- Use of a difficult-to-machine material

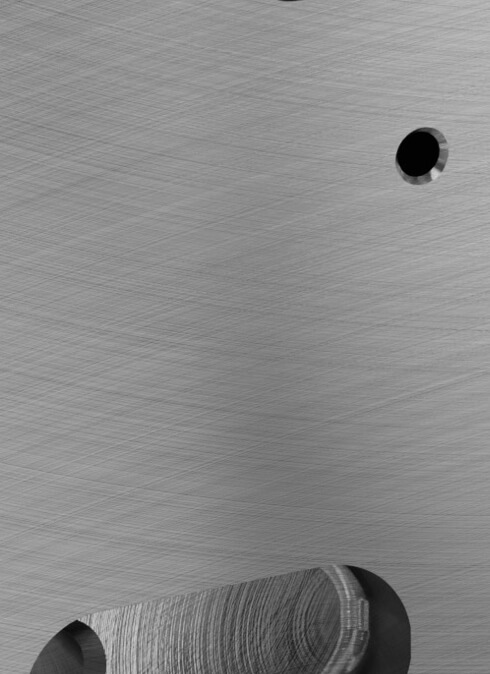

- Milled surfaces with a ground-like appearance

- High precision with simultaneous production-ready series manufacturing

- Iterative alignment between design and feasible production

HSP supported a globally operating company in the field of hydrogen technology and plant engineering for the energy industry in making a custom component ready for series production. The component was theoretically and constructively designed by the customer as part of a new development. In close

collaboration with the customer, the complex component was to be brought from prototype to series production readiness within the shortest possible time.

Special technical challenges:

- Complex, angular geometry with tight form and position tolerances

- Use of a difficult-to-machine material

- Milled surfaces with a ground-like appearance

- High precision with simultaneous production-ready series manufacturing

- Iterative alignment between design and feasible production

RESULT

From prototype to series production – precisely and scalably manufactured

The components were adapted to the limits of what is feasible in several iterative steps together with the customer. With modern CNC milling and profound expertise, a practical, production-technically feasible compromise between design and manufacturing was achieved. Today, the component is manufactured scalably in series.

What we have done

From theoretical design to a series-ready stainless steel milled part

Thanks to our experience with complex stainless steel parts and demanding materials, we were able to realize the project with high precision:

- Establishment of an interdisciplinary project team

- Development of manufacturing strategies to achieve maximum precision

- Iterative alignment between customer design and manufacturing capabilities

- Scaling from prototype to series production while maintaining surface quality in a short time

The complex component could thus be successfully integrated into the customer’s series solutions within a few months.