Series production

readiness Manufacturing

evolution for large-format

custom-made parts

Case Study Rolling Bearing Industry

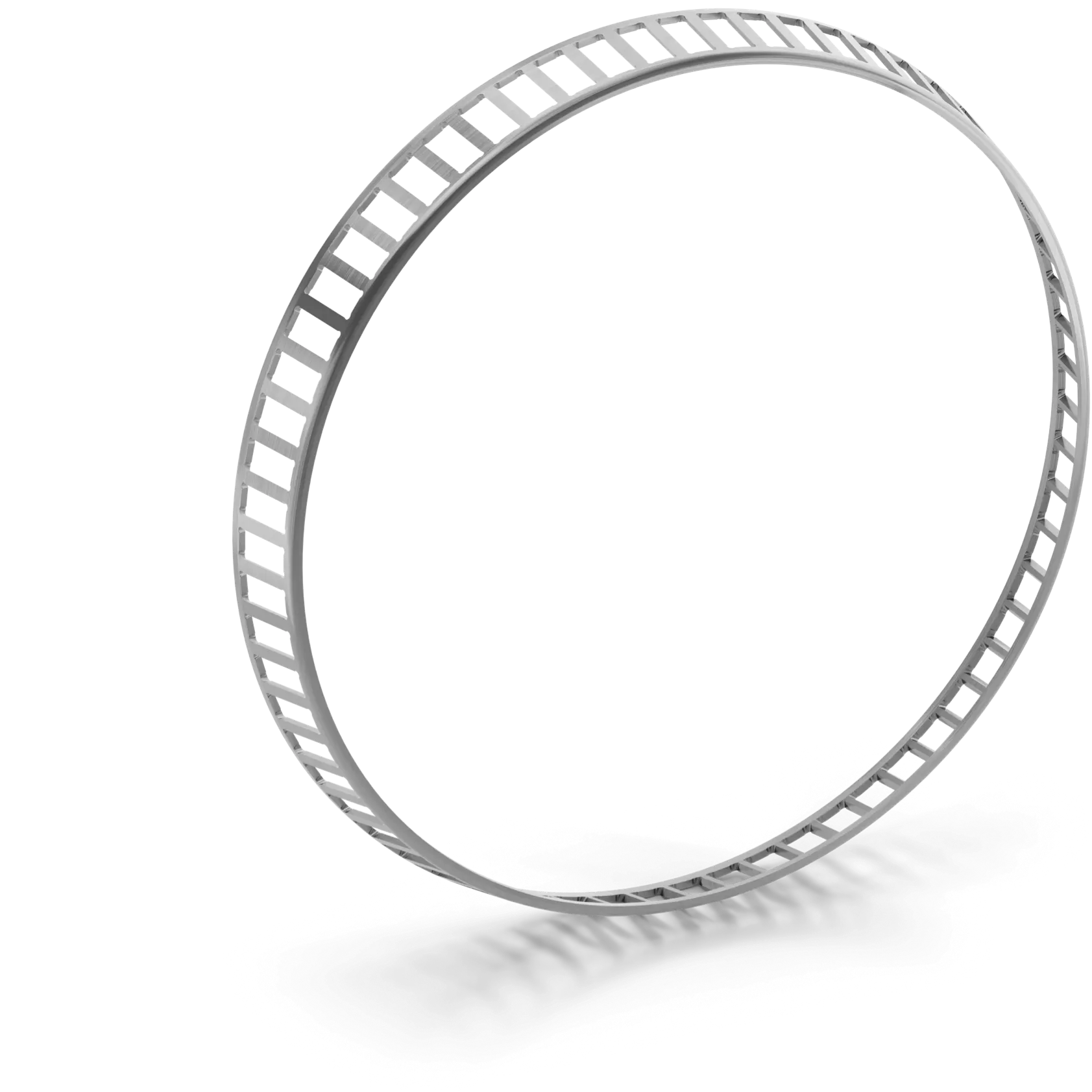

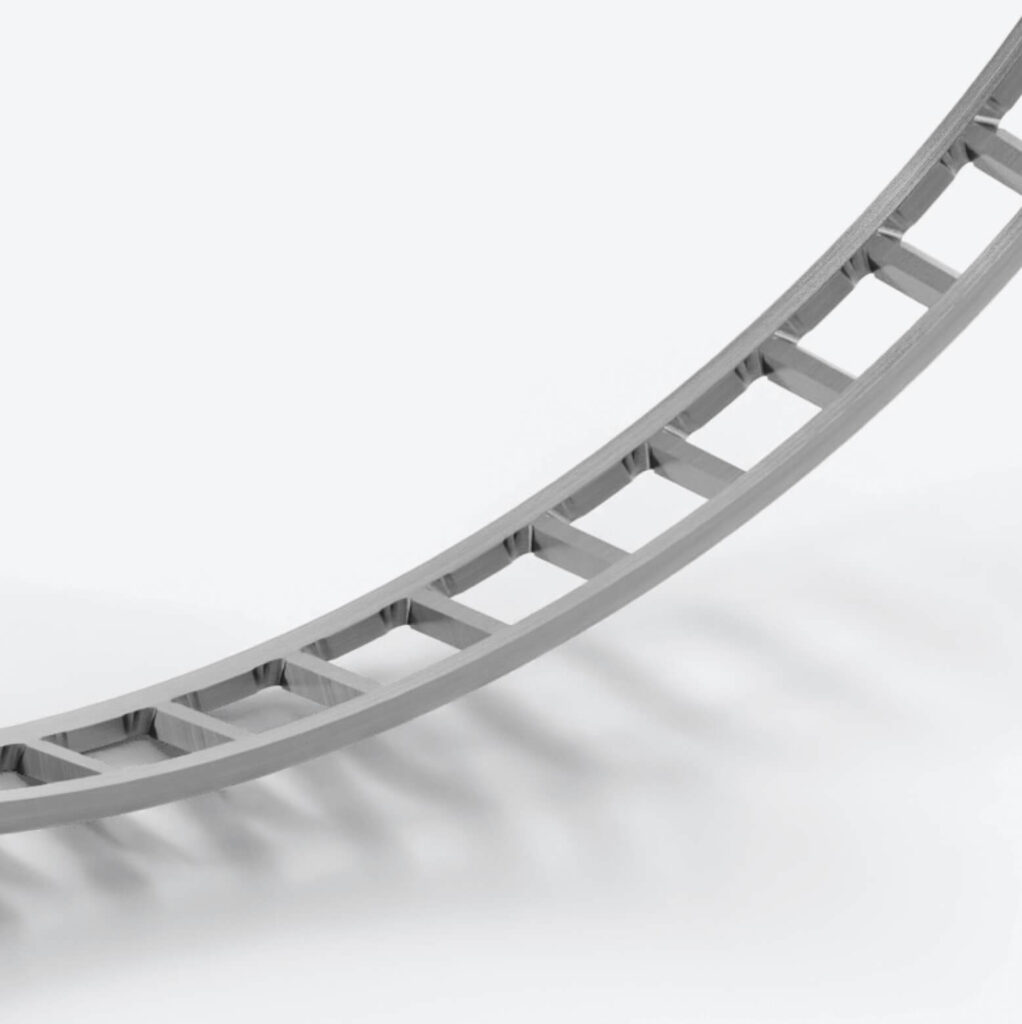

Efficient series production of a large-format flow-formed part for tapered roller bearings in wind turbines

Flow-formed part Drawing part

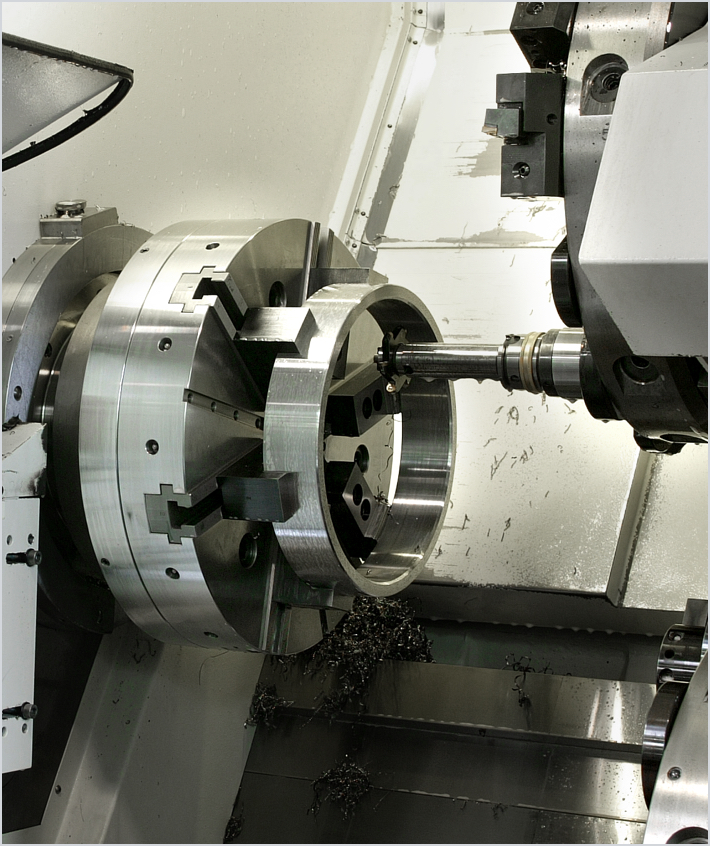

Task: An international manufacturer from the rolling bearing industry commissioned HSP to develop and mass-produce a supporting component for tapered roller bearings in wind turbines.

Solution: Starting from a complex turned and milled part, a new, patented manufacturing technology was developed over several development phases, which significantly reduces costs, material usage and resource consumption – while maintaining the same level of precision.

Dimension | Material & Hardness | Tolerances & Quality |

|

|

|

Flow-formed part Drawing part

Challenge

Scaling, precision and economy in XXL format

HSP was commissioned by an internationally active company from the rolling bearing industry to manufacture a supporting component in tapered roller bearings for large-scale applications, particularly in the field of wind turbines. The customer-specific turned and milled part was to be used as an interface for bearing guidance and load transmission. As part of a product evolution, existing bearing solutions with smaller diameters were to be transferred to significantly larger dimensions.

The existing production process had to be

- structurally scaled,

- rethought for larger diameters,

- economically transferred to series production

become. The challenge was the combination of high dimensional accuracy, complex manufacturing steps and the need to ensure economical scalability already in the design phase.

HSP was commissioned by an internationally active company from the rolling bearing industry to manufacture a supporting component in tapered roller bearings for large-scale applications, particularly in the field of wind turbines. The customer-specific turned and milled part was to be used as an interface for bearing guidance and load transmission. As part of a product evolution, existing bearing solutions with smaller diameters were to be transferred to significantly larger dimensions.

The existing production process had to be

- structurally scaled,

- rethought for larger diameters,

- economically transferred to series production

become. The challenge was the combination of high dimensional accuracy, complex manufacturing steps and the need to ensure economical scalability already in the design phase.

RESULT

Marketable series solution for large bearings in the wind power sector

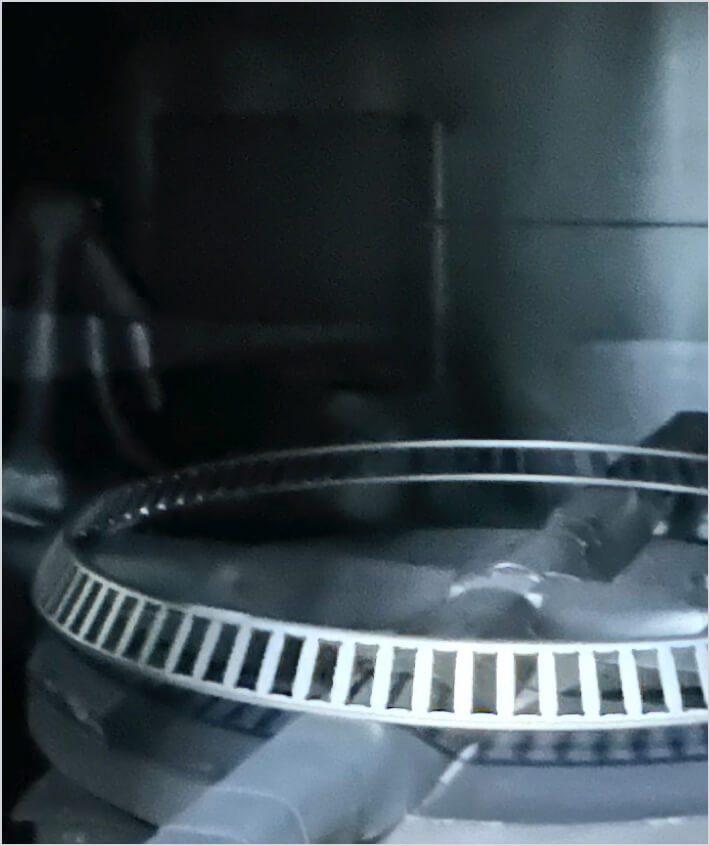

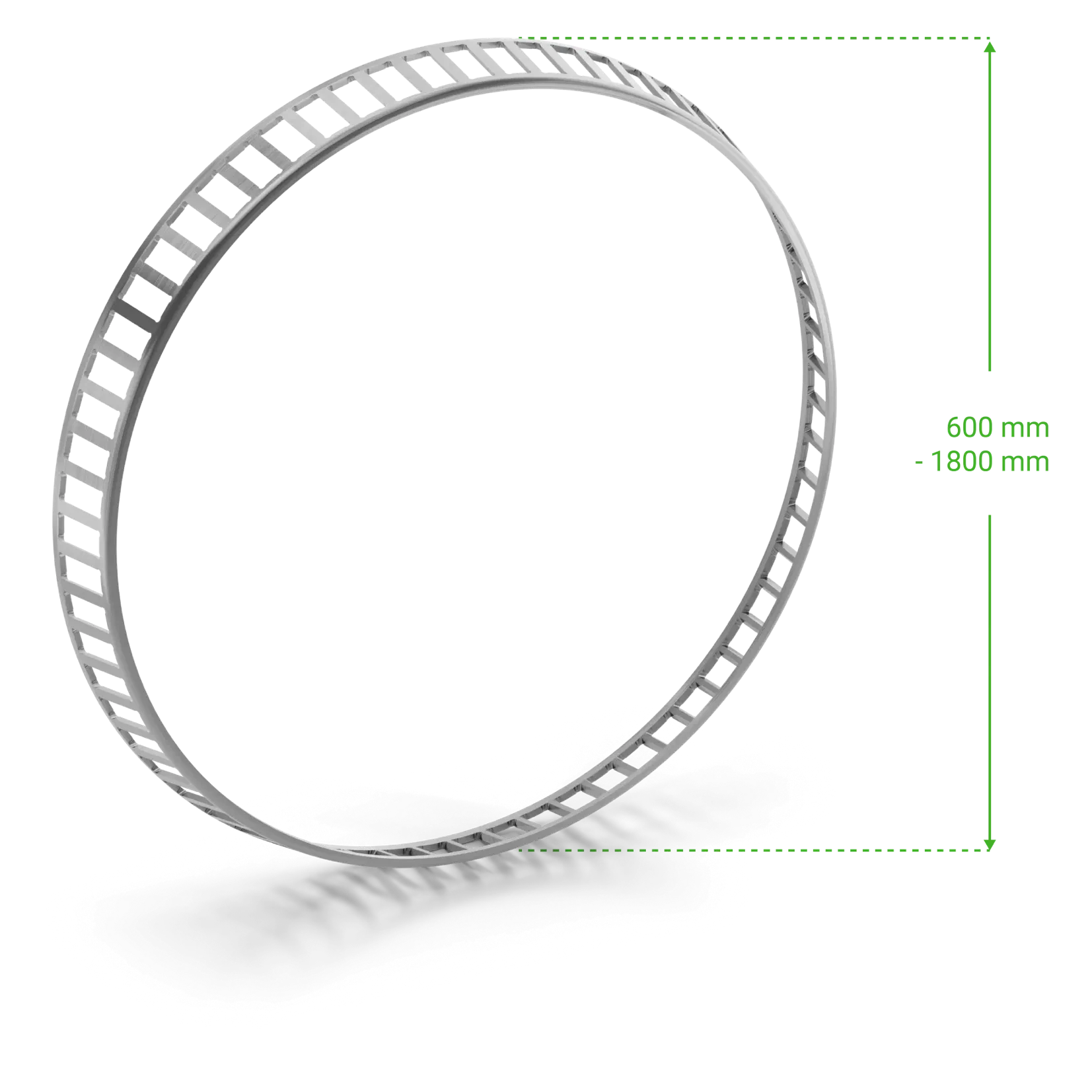

In close cooperation with the customer, a fully transferable manufacturing and design concept for new sizes was developed, which successfully enabled market entry into new performance dimensions. Initially, the component was turned and milled based on existing manufacturing technologies and successfully put into series production. In the next development step, HSP independently developed and patented the manufacturing technology – the so-called flow forming technology for diameters of 600-1,800 mm.

The components are made of high-quality steel sheet and are manufactured in several, precisely coordinated manufacturing steps:

- Flow formed for preforming

- Blasted to ensure a uniform surface and material compatibility

This process combines material efficiency, high dimensional accuracy and reduced processing times, resulting in significant cost advantages in series production.

From a long-term perspective, HSP is already working on the next stage of evolution – the integration of laser processing for even more precise and resource-saving processes.

In close cooperation with the customer, a fully transferable manufacturing and design concept for new sizes was developed, which successfully enabled market entry into new performance dimensions. Initially, the component was turned and milled based on existing manufacturing technologies and successfully put into series production. In the next development step, HSP independently developed and patented the manufacturing technology – the so-called flow forming technology for diameters of 600-1,800 mm.

The components are made of high-quality steel sheet and are manufactured in several, precisely coordinated manufacturing steps:

- Flow formed for preforming

- Blasted to ensure a uniform surface and material compatibility

This process combines material efficiency, high dimensional accuracy and reduced processing times, resulting in significant cost advantages in series production.

From a long-term perspective, HSP is already working on the next stage of evolution – the integration of laser processing for even more precise and resource-saving processes.

What we have done

Services at a glance: competently supported in every project phase

Based on decades of experience with complex rolling bearing components and a deep understanding of systems, we have specifically embarked on the development of an innovative manufacturing strategy:

- Composition of an overarching project team

- New design in 3D, tailored to internal manufacturing processes

- Development of efficient manufacturing strategies with a focus on cost and resource efficiency

- Development of proprietary manufacturing technologies and a patented process

- Precision manufacturing through coordinated processes: flow forming, blasting

- marketable series production with maximum dimensional accuracy and repeatability

- Quality assurance through optical measurement and documented process reliability

- Scaling to different sizes – from small to large series

- Automation and process innovations for sustainable cost optimization

Thanks to the manufacturing process innovations developed and patented internally by HSP, not only could up to 80% of material be saved, but CO₂ emissions could also be significantly reduced – while maintaining the same level of performance. A double success story, technologically and ecologically. This resulted in a fully transferable manufacturing and design concept for new sizes, which successfully enabled market entry into new performance dimensions.