Withdrawal Sleeves –

for easy and safe

bearing disassembly

HSP withdrawal sleeves enable damage-free removal of rolling bearings with tapered bores. Our adapter sleeves are immediately available in metric, imperial, and custom designs.

HSP Withdrawal Sleeves

Damage-free bearing disassembly – fewer complaints, more customer satisfaction

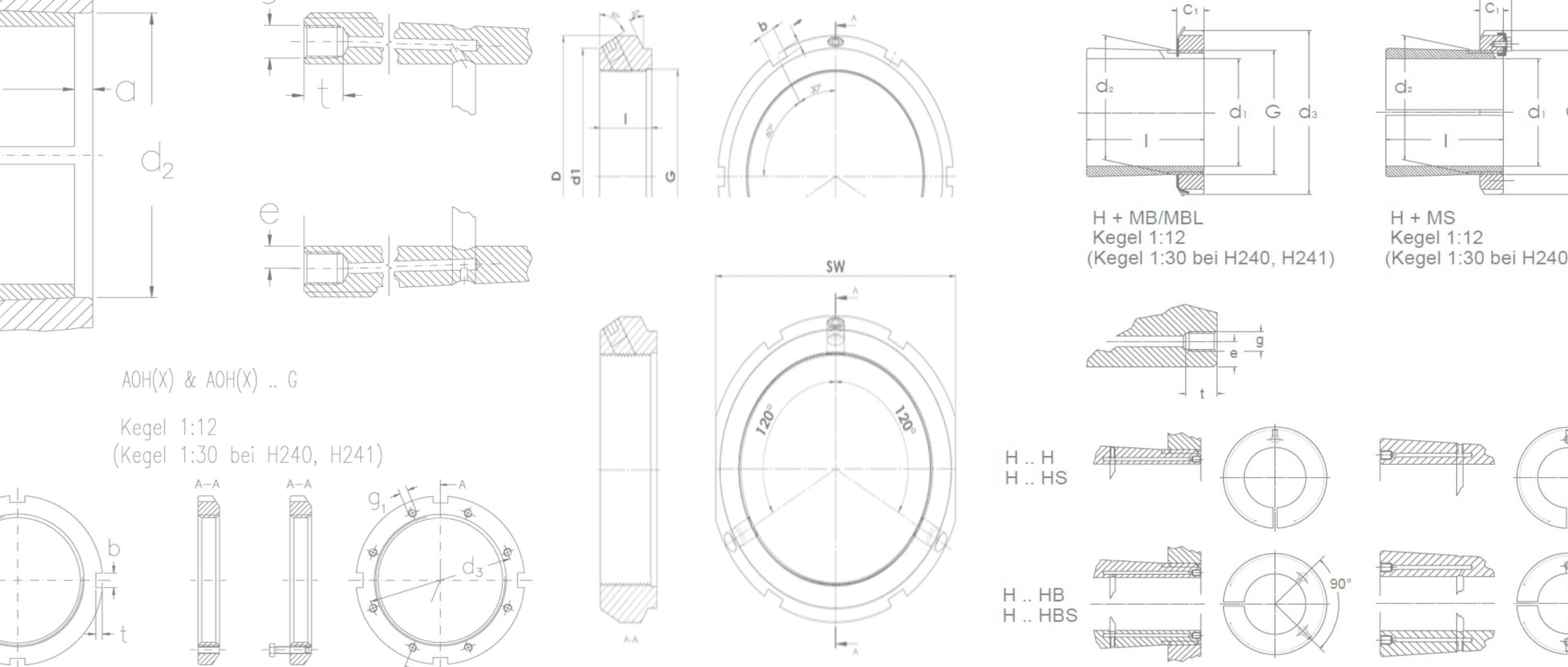

Manufactured according to DIN 5416 and DIN ISO 2982-1, HSP withdrawal sleeves are 100% compatible with standard market systems. Whether compact standard types or large-dimensioned special designs up to 1,400 mm: Our products are available in metric, imperial, or custom variants, each with and without oil channels. With solutions from HSP Components, you rely on withdrawal sleeves that

simplify the assembly process and reduce complaints. Through intelligent standardization of threads, we reduce part variety and optimize your inventory management – for greater efficiency, safety, and cost-effectiveness in specialized trade.

Manufactured according to DIN 5416 and DIN ISO 2982-1, HSP withdrawal sleeves are 100% compatible with standard market systems. Whether compact standard types or large-dimensioned special designs up to 1,400 mm: Our products are available in metric, imperial, or custom variants, each with and without oil channels. With solutions from HSP Components, you rely on withdrawal sleeves that

simplify the assembly process and reduce complaints. Through intelligent standardization of threads, we reduce part variety and optimize your inventory management – for greater efficiency, safety, and cost-effectiveness in specialized trade.

HSP Withdrawal Sleeves: Technical Perfection,

that pays off

Precisely manufactured according to DIN 5416 & ISO 2982-1 for maximum compatibility and reliability in industrial use.

Standardized and custom variants with lengths up to 800 mm – immediately available from stock.

For controlled pressure build-up and damage-free disassembly, even with large bearings and confined installation spaces.

Less part variety, more efficient inventory management, and fewer sources of error in assembly and purchasing.

For easy inventory, safe handling, and full traceability in specialized trade.

Combinable with lock nuts, locking washers, and assembly aids – all perfectly coordinated.

Compatible with common OEM products – without adaptation effort or additional costs.

Immediately available – even for large call-off quantities thanks to our own logistics center.

HSP withdrawal sleeves are available in metric, imperial, or custom designs.

Precise disassembly solutions for rolling bearings

Withdrawal sleeves with oil channels for efficient disassembly

When bearings need to be replaced, nothing can go wrong. HSP hydraulic withdrawal sleeves facilitate the removal of tapered rolling bearings – precisely, with positive locking, and without damage. The integrated oil channel system distributes pressure evenly, protects components and tools, and ensures predictable, fast maintenance processes.

For dealers, this means: With HSP withdrawal sleeves, you can offer your customers reliable, assembly-friendly solutions that reduce downtime and increase bearing lifespan. Immediately available sizes, thread types, and special designs enable flexible solutions for every industrial application.

When bearings need to be replaced, nothing can go wrong. HSP hydraulic withdrawal sleeves facilitate the removal of tapered rolling bearings – precisely, with positive locking, and without damage. The integrated oil channel system distributes pressure evenly, protects components and tools, and ensures predictable, fast maintenance processes.

For dealers, this means: With HSP withdrawal sleeves, you can offer your customers reliable, assembly-friendly solutions that reduce downtime and increase bearing lifespan. Immediately available sizes, thread types, and special designs enable flexible solutions for every industrial application.

Service & Support for specialist dealers

Additional services for our products

In addition to first-class products, you benefit from comprehensive services at HSP – from technical consulting and flexible logistics to individual production according to drawings.

FAQ – Frequent

questions about

services &

withdrawal

sleeves from

HSP Components

Our withdrawal sleeves are precisely manufactured according to DIN 5416 and ISO 2982-1 and offer maximum dimensional accuracy for the aftermarket. They are 1:1 compatible with standard market systems.

HSP withdrawal sleeves cover outer diameters up to Ø1,400 mm and lengths up to 800 mm. This allows dealers to serve a wide range of rolling bearings with standardized or custom solutions.

Yes, our withdrawal sleeves are specially developed for the aftermarket and industrial applications. Dealers benefit from high availability, precisely fitting components, and complementary services such as consulting and special type manufacturing.

The hydraulic withdrawal sleeves enable even pressure build-up, protect bearings and tools, and guarantee process-reliable, damage-free disassembly – ideal for maintenance and heavy-duty bearings.

Yes, HSP offers custom manufacturing of special types, with abnormal bores, deviating from standard dimensions, or with special oil channels, which can be flexibly integrated into the product range of power transmission dealers.

Our withdrawal sleeves comply with DIN 5416, ISO 2982-1, and other OEM quality standards, enabling dealers to offer safe, durable, and reliable spare parts for rolling bearings.

Through our B2B shop, specialized dealers can conveniently reorder withdrawal sleeves 24/7. All items are individually packed, barcoded, and optimized for fast inventory management.

HSP withdrawal sleeves can be perfectly combined with lock nuts, locking elements, and assembly materials to ensure a complete, process-reliable solution for your customers.