Ready to mount

custom-made parts and

custom fabrications

HSP Components manufactures precise custom-made parts and custom fabrications according to individual specifications. We deliver tailored solutions for demanding applications – from prototype to series production.

When standard is not enough

Custom fabrications from high-performance materials and with complex geometries

Where standard solutions reach their limits, the strength of HSP Components begins.

Whether complex geometries, filigree structures in XXL dimensions, difficult-to-machine high-performance materials, or safety-critical components with extensive certification and

documentation requirements – we are “Experts for Extremes”. With a wide range of processing options, we advise you on the most economically efficient manufacturing method and intelligently combine processes to realize your custom-made parts. Our strength lies in the combination of a broad manufacturing spectrum, state-of-the-art measurement technology, and intelligent, digitized processes. We can flexibly produce even highly complex custom fabrications in series. Our competencies prove themselves where precision, resilience, and documentation security are crucial – from aerospace to power plant construction.

Where standard solutions reach their limits, the strength of HSP Components begins.

Whether complex geometries, filigree structures in XXL dimensions, difficult-to-machine high-performance materials, or safety-critical components with extensive certification and

documentation requirements – we are “Experts for Extremes”. With a wide range of processing options, we advise you on the most economically efficient manufacturing method and intelligently combine processes to realize your custom-made parts. Our strength lies in the combination of a broad manufacturing spectrum, state-of-the-art measurement technology, and intelligent, digitized processes. We can flexibly produce even highly complex custom fabrications in series. Our competencies prove themselves where precision, resilience, and documentation security are crucial – from aerospace to power plant construction.

High-end manufacturing for highly complex requirements

Certified manufacturing for Ready to mount custom-made parts – from XXS to XXL

Thanks to state-of-the-art manufacturing technologies and high vertical integration, we realize custom fabrications in every dimension – from filigree precision parts to XXL components up to Ø 4,000mm outer diameter, 1,000mm length, and 20t weight. Our digital process chain enables consistently high quality and rapid scaling from individual pieces to series production.

Machining Capabilities at a Glance

Manufacturing processes for demanding special components

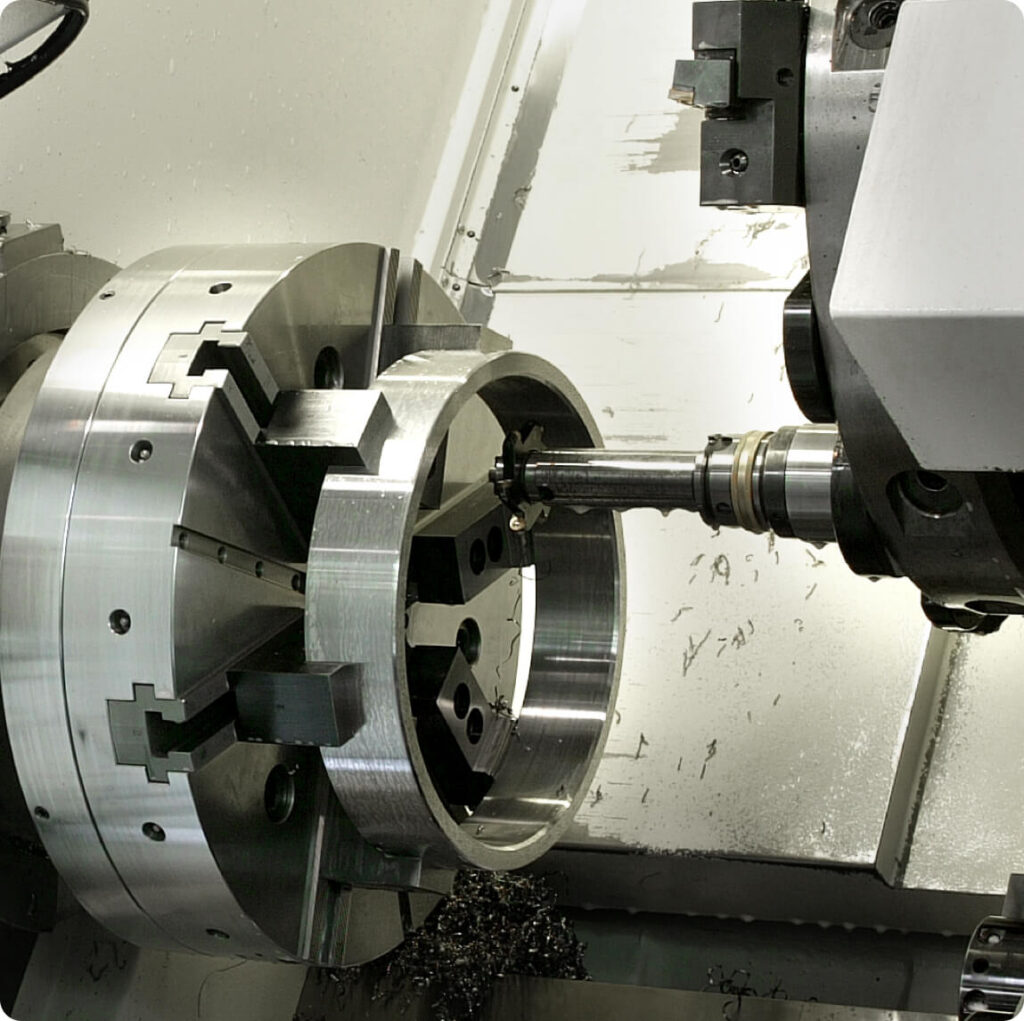

With 4-axis turning, we precisely manufacture rotationally symmetrical parts – even in hardened condition – up to Ø 4,000 mm. Ideal for bearing cages, rings, flanges, and components in tool and mold making. We also impress with dimensional accuracy and process stability even with high-strength materials such as Inconel or titanium.

With 5-axis machining, we realize highly complex metal milled parts – from filigree structures to XXL components (up to 4,500 x 4,500 x 1,500 mm). Thanks to HSC and hard milling, we efficiently process even hardened materials – also for tool and mold making.

Our patented flow forming process replaces classic forming techniques – entirely without a die. The result: up to 80% less material consumption with consistent quality. Ideal for large rotationally symmetrical components in medium series. Resource-efficient and CO₂-reducing.

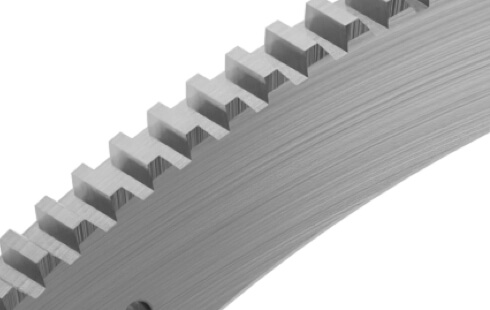

We mill gear teeth on rotationally symmetrical components with outer diameters up to Ø 4,000 mm. Ideal for large gears, couplings, or special solutions in drive technology and rolling bearing technology.

With selective laser melting (SLM), we quickly manufacture prototypes and series parts with complex geometries – ideal when classic methods reach their limits. Also suitable for tool and mold making, e.g., for internal structures or conformal cooling.

Our manufacturing continues to evolve: Soon, 5-axis laser cutting will complement our portfolio – for the precise, efficient, and geometry-independent processing of complexly shaped 3D components.

From Prototype to Series

Craftsmanship expertise

meets series production –

precision in every

production step

Our manufacturing begins where others reach their limits – delivered with micrometer precision, economically, and ready to mount. HSP Components combines the precision of a manufactory with the efficiency of series production. Thanks to digitized processes, modern measurement technology, and certified quality assurance, we reliably bring highly complex custom-made parts into series production – economically, reproducibly, and documented.

Whether XXL components with up to 4,000 mm diameter or safety-critical components made from difficult-to-machine materials: We deliver precision in every batch – ready to mount and on schedule.

Technological

manufacturing

expertise for

precise

custom-made

parts – from

XXS to XXL

- Turning (4-axis)

- Milling (3&5-axis)

- Gear Milling

- Flow Forming

- Additive Manufacturing

- Surface Treatment

- Assembly

- Labeling | Marking

- Measurement + Testing

Round Components:

- Ø10 – 4,000 mm (OD)

- 100 – 1,000 Length

Rectangular Components:

- 4,500 x 4,500 x up to 1,500 (LxWxH)

max. workpiece weight:

- up to 20 t

max. workpiece weight (air handling):

- 10 t

All common materials

Cast iron materials

- Cast steel

- Cast iron

Advanced Materials | Exotic materials

- Nickel alloys (Inconel, Monel, Hastelloy)

- Carbides

- Duplex steels

- Titanium and titanium alloy

Steel

- Low-alloy structural steels

- Chrome steels (heat-treated / hardened)

- Case-hardening / Quenched and tempered steel

- Stainless steel (V2A)

- Stainless steel (acid-resistant V4A)

- Free-cutting steel

- Tool steel

- Cold extrusion steel

Light metals

- Aluminum and aluminum alloy

- Magnesium

- phosphated

- zinc-plated

- galvanized

- Dimensional accuracy for roundness up to 0.02 mm

- Wall thickness variations up to 0.001 mm

Benefits of Collaborating with HSP Components

Expert in customer-specific special solutions & Ready to mount custom-made parts

HSP Components combines decades of experience with innovative and partially patented manufacturing processes.

This combination enables highly precise, economical, and scalable production – even with complex geometries or difficult-to-machine high-performance materials.

With clients from the rolling bearing industry, plant and mechanical engineering, energy and defense technology, as well as aerospace, HSP possesses deep application knowledge in safety-critical industries. This expertise is incorporated into every custom fabrication – for solutions that impress in all dimensions.

With digitized production planning, modular processes, and high vertical integration, we flexibly scale from individual fabrications to series production. This results in precise and economical solutions – even for complex large components and XXL precision parts with the highest quality requirements.

Our manufacturing combines the precision of a manufactory with the efficiency of series production. With state-of-the-art measurement technology, digital production planning, and certified processes, we guarantee consistent quality – from prototype to large-scale series production.

Whether safety-critical components or applications with high verification requirements – HSP delivers all manufacturing steps with complete documentation and certified testing processes. This ensures your custom fabrications meet all OEM and industry standards – traceable and auditable.

HSP Components ensures that your Ready to mount components arrive exactly when and where they are needed. With flexible logistics solutions – from pre-assembly and customer-specific packaging to Just-in-Time delivery – we seamlessly integrate into your production processes. Our logistics expertise reduces storage costs, secures supply, and ensures maximum efficiency in procurement and assembly.

Upon request, HSP offers full service along the entire process chain: from procurement, CNC manufacturing, and assembly to the logistics of Ready to mount precision parts in OEM quality. This results in stable processes, short lead times, and reliable series results.

Through targeted refurbishment, we extend the lifespan of critical components, reduce downtime, and lower procurement costs. With state-of-the-art measurement technology and documented testing procedures, we ensure that refurbished components meet the same quality standards as new parts – precise, process-reliable, and sustainable.

HSP sees itself not just as a manufacturer, but as a development partner.

Together with you, we optimize component geometries, material selection, and manufacturing steps – for more functionality, lower costs, and maximum process reliability.

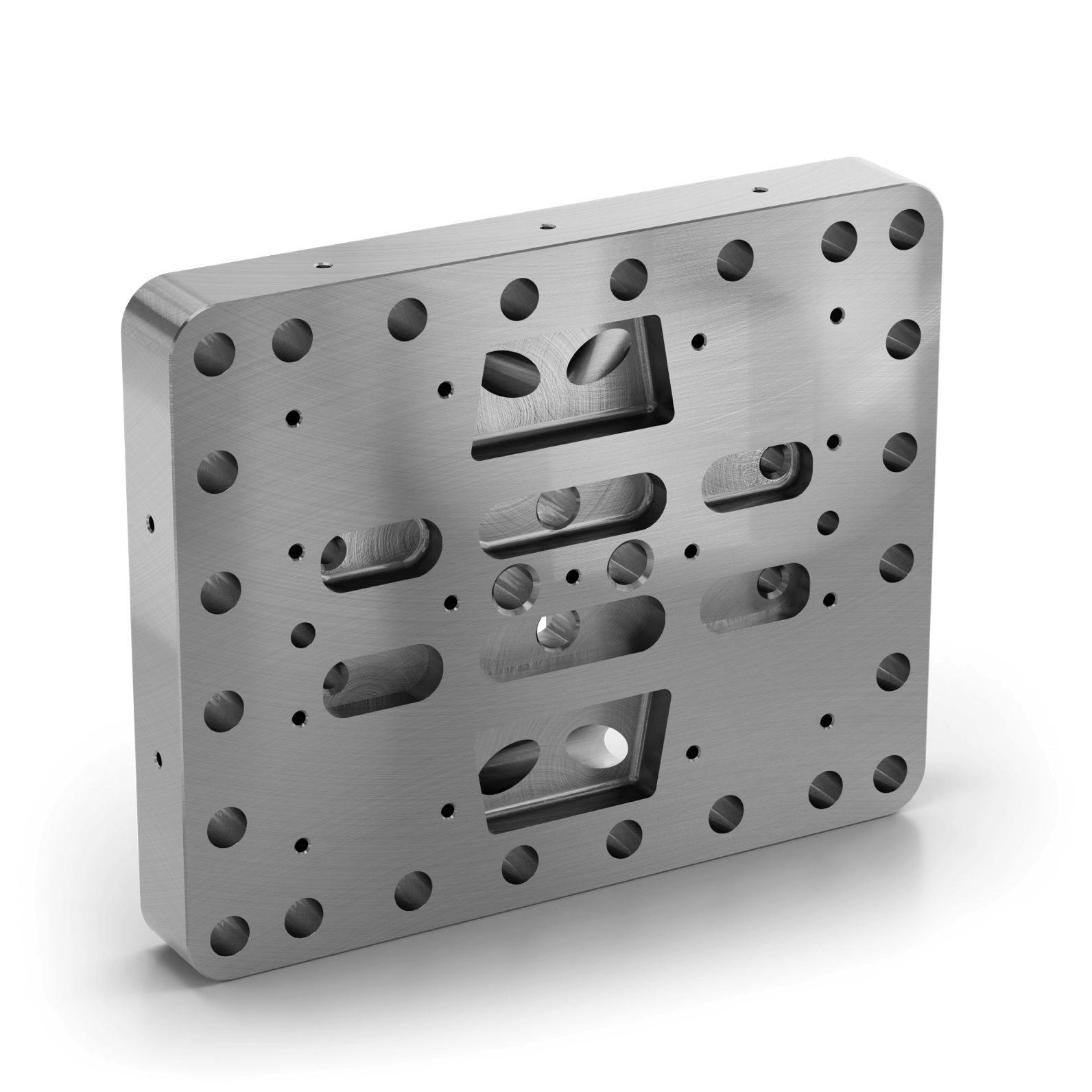

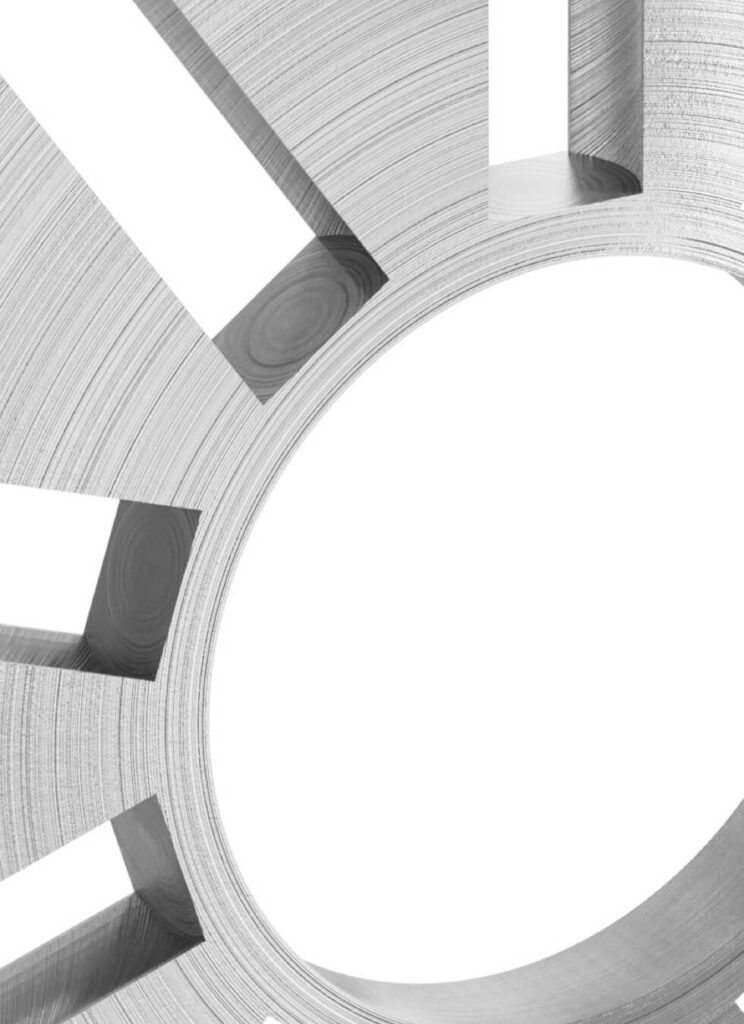

Work Samples of Our Manufacturing Expertise

Successful Custom Fabrications for Demanding Industrial Sectors

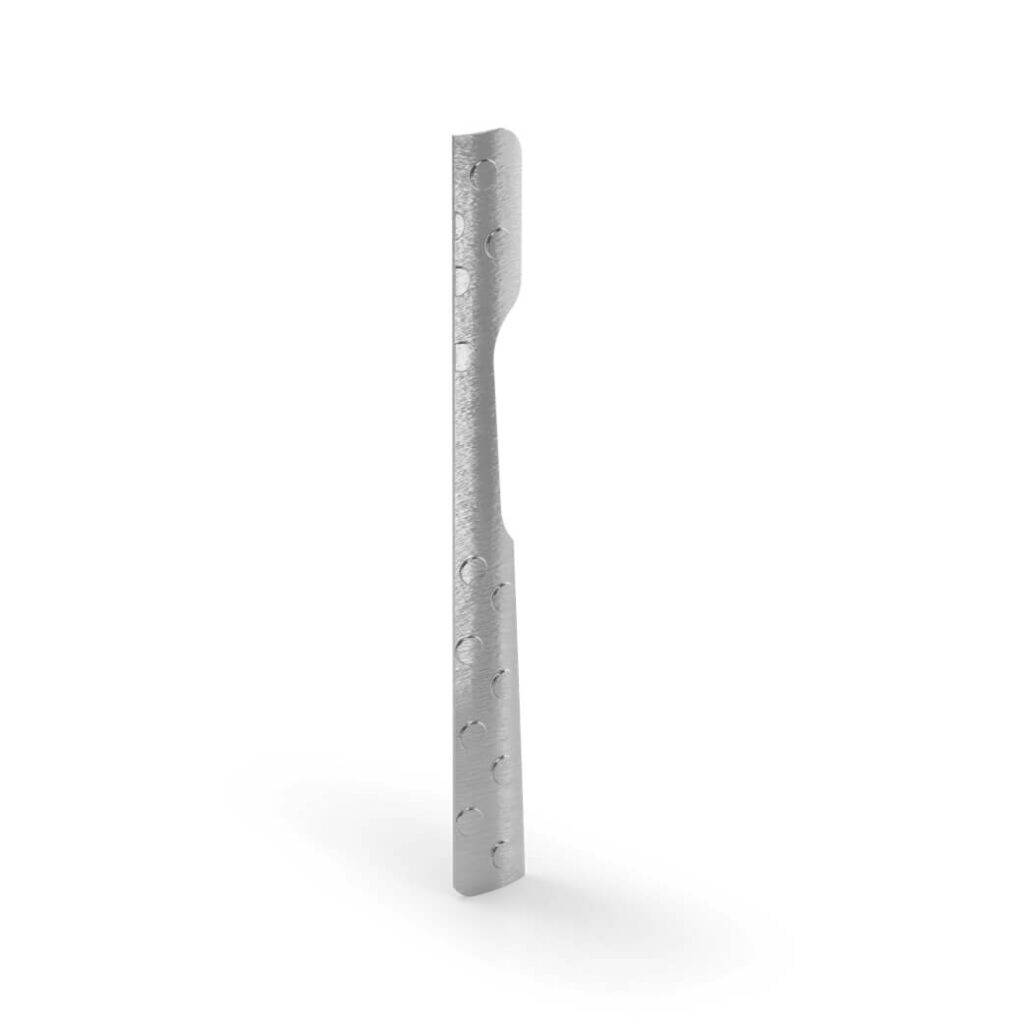

Even though many of our projects are confidential, we offer you an insight into our manufacturing expertise. The custom-made parts shown have been graphically altered for reasons of discretion and exemplify our strength in processing complex geometries, demanding surfaces, and difficult-to-machine materials. HSP Components regularly manufactures individual

special components such as guide rings, hydraulic nuts, or hard-turned precision parts – exactly according to customer specifications.

Would you like to learn more about the challenges behind our projects?

Even though many of our projects are confidential, we offer you an insight into our manufacturing expertise. The custom-made parts shown have been graphically altered for reasons of discretion and exemplify our strength in processing complex geometries, demanding surfaces, and difficult-to-machine materials. HSP Components regularly manufactures individual

special components such as guide rings, hydraulic nuts, or hard-turned precision parts – exactly according to customer specifications.

Would you like to learn more about the challenges behind our projects?

Thin-walled Aluminum Discs Drawing part

Challenge: Milled, thin-walled aluminum discs tend to warp extremely, mostly only after the last work step. HSP possesses specialized knowledge and procedures to prevent this.

Solution: Through special clamping technology and specially developed manufacturing processes, HSP ensures that even filigree, milled aluminum custom-made parts remain dimensionally stable and accurate – precisely manufactured, delivered ready to mount.

Dimension | Material | Manufacturing Process |

|

|

|

Thin-walled Aluminum Discs Drawing part

Large Ring with External Gearing Drawing part

Challenge: Large-diameter externally geared rings usually require special machines – a costly endeavor.

Solution: HSP efficiently manufactures such large components through precise gear milling on existing milling machines. This reduces manufacturing times and costs – while maintaining dimensional accuracy and process reliability.

Dimension | Material | Manufacturing Process |

|

|

|

Large Ring with External Gearing Drawing part

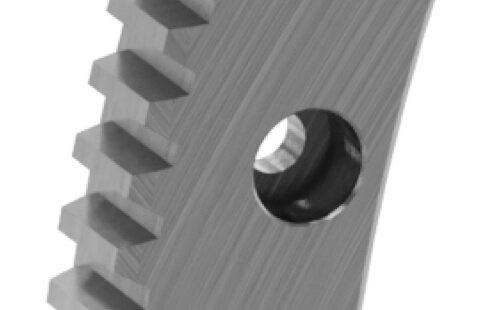

Halved Clamping Ring Drawing part

Challenge: Halved clamping rings shift after splitting. HSP avoids this with its own technologies.

Solution: With its own clamping technologies and experienced manufacturing personnel, HSP avoids displacement and ensures precision during assembly – even with complex, split rolling bearing rings.

Dimension | Material | Manufacturing Process |

|

|

|

Halved Clamping Ring Drawing part

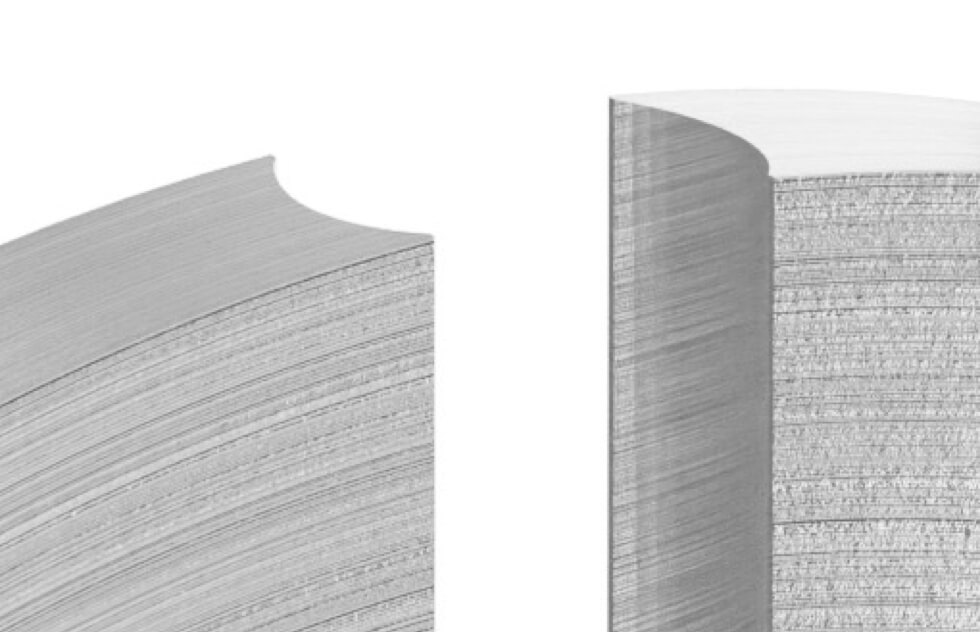

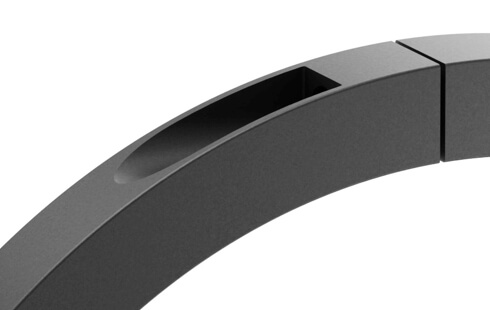

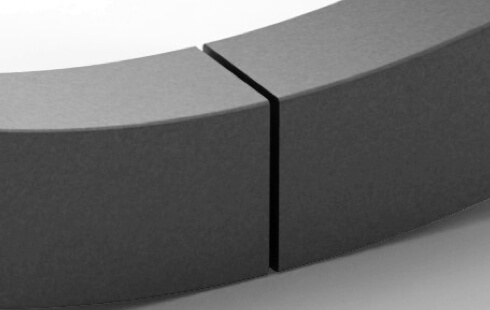

3D-Printed Arch Drawing part

Challenge: Whenever internal geometries are not accessible or manufacturable with conventional manufacturing processes, metallic 3D printing comes into play.

Solution: HSP uses selective laser melting to manufacture highly precise arches and complex custom-made parts from steel and stainless steel. This results in filigree, functionally integrated components that are perfectly suited for demanding industries – precise, resilient, and ready to mount.

Dimension | Material | Manufacturing Process |

|

|

|

3D-Printed Arch Drawing part

Custom-Made Parts Services

Complex Components. Demanding Materials. Reliable Implementation.

Would you like to learn more about our services for demanding custom fabrications? Discover our comprehensive services for custom-made parts – from feasibility analysis to Just-in-Time delivery of Ready to mount custom fabrications.