Quality in Series –

Precision that

scales

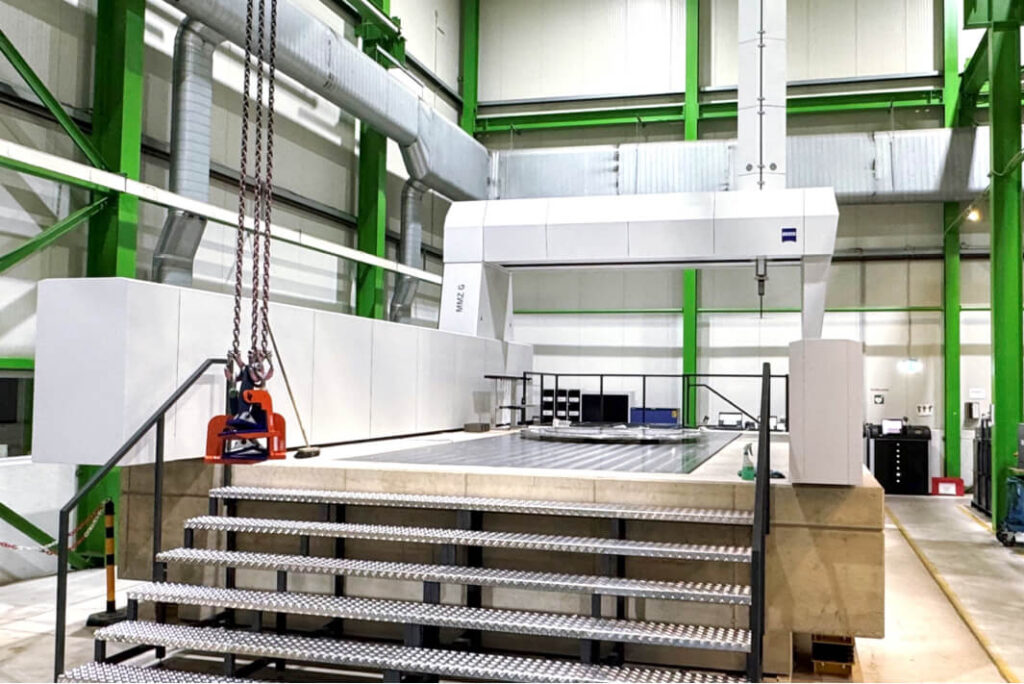

With state-of-the-art measurement technology, digital process monitoring, and certified procedures, we consistently ensure the highest quality – from prototype to large-scale production.

Quality Assurance

Downloads, Certificates & Documentation

Management Systems

ISO 9001/14001 (DT)

HSP is certified according to ISO 9001 and ISO 14001 – for the highest quality standards and consistent environmental management.

ISO 9001/14001 (TR)

Certification in preparation: HSP is currently preparing the certification of the Turkish plant according to ISO 9001 and ISO 14001 .

DIN EN 9100

Certification in preparation: HSP is currently preparing the certification according to the quality standard of the aerospace industry.

Re-stamping authorization

Certificate for the transfer of the marking of materials in accordance with the applicable standards and customer specifications.

AEOC certificate

HSP has been certified as an Authorized Economic Operator (AEO) since 2011 (DE002600) and thereby strengthens the security and reliability of its supply chain in international trade.

Green electricity certificate

HSP obtains 100% of its electricity from renewable energy plants in accordance with statutory environmental standards.