HSP Schwahlen 74 days ago

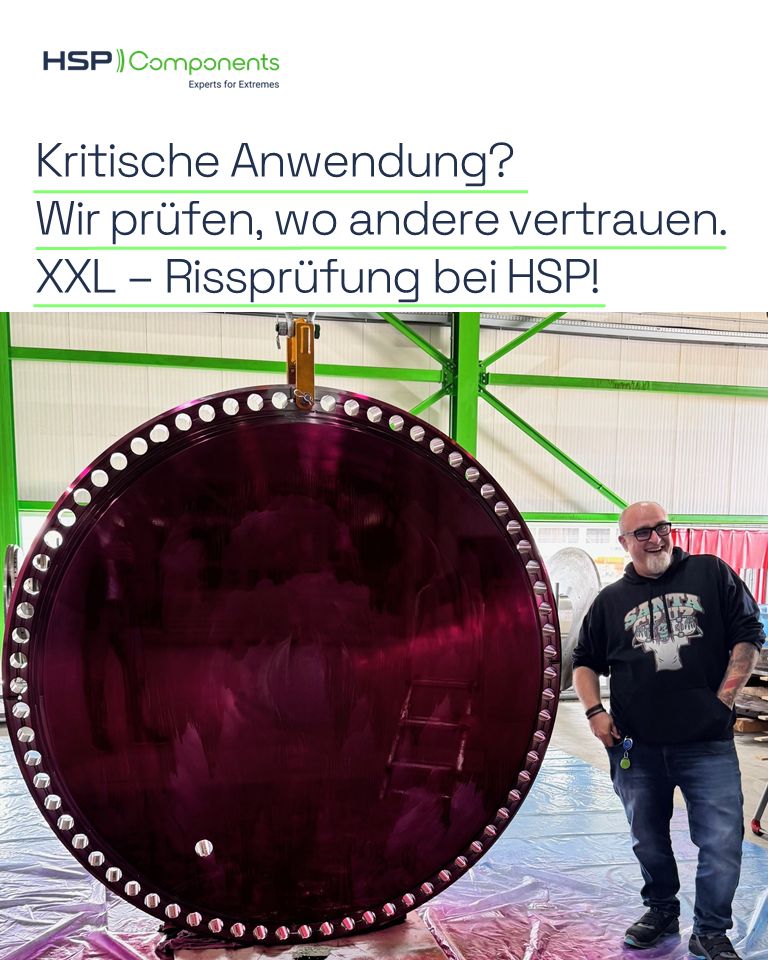

🔍 Wir prüfen, wo andere vertrauen. XXL – Rissprüfung bei HSP! Wenn

…more

HSP Components develops and manufactures rolling bearing components and complex custom-made parts that function reliably even under extreme conditions.

Who We Are

HSP Components is an internationally active premium manufacturer of precision components for the rolling bearing industry and other high-tech sectors. We combine decades of manufacturing experience, engineering expertise, and state-of-the-art CNC technologies to produce complex

metal components reliably, economically, and with a perfect fit. As a technology partner, we support our customers along the entire value chain – from design and series production to assembly. With individual logistics solutions and the assumption of entire process chains, we accompany them throughout the entire product life cycle, if desired.

Since 2024, in addition to our headquarters in Germany, we also manufacture in Izmir (Turkey). The new location expands our capacities for the series production of complex metal components and strengthens our international delivery and competitiveness.

HSP Components is an internationally active premium manufacturer of precision components for the rolling bearing industry and other high-tech sectors. We combine decades of manufacturing experience, engineering expertise, and state-of-the-art CNC technologies to produce complex

metal components reliably, economically, and with a perfect fit. As a technology partner, we support our customers along the entire value chain – from design and series production to assembly. With individual logistics solutions and the assumption of entire process chains, we accompany them throughout the entire product life cycle, if desired.

Since 2024, in addition to our headquarters in Germany, we also manufacture in Izmir (Turkey). The new location expands our capacities for the series production of complex metal components and strengthens our international delivery and competitiveness.

Our Commitment

Whether extreme tolerances, exceptional materials, or safety-critical applications: HSP Components stands for high-tech manufacturing that pushes boundaries. With engineering knowledge, process intelligence, and digital precision, we advance technologies to make components economically scalable and long-term available.

Under the brand HSP Components, we will communicate worldwide the expertise and innovative strength previously known under HSP Schwahlen – as a clear sign of growth, further development, and international orientation.

WHY HSP?

Manufacturing of complex XXS components up to delicate XXL parts: We realize components across the entire size spectrum and apply the highest precision in both the smallest and largest dimensions.

From standard steels to difficult-to-machine nickel and titanium alloys: For decades, we have mastered the processing of the most demanding materials, thus ensuring maximum performance under extreme conditions.

Seamless documentation and complete traceability: Each component is comprehensively documented and manufactured with traceability, allowing us to reliably meet even the highest safety requirements.

for cost-intensive XXL components and sensitive applications: Through controlled manufacturing processes, we completely avoid errors and guarantee the impeccable quality of every delivery.

Agile manufacturing and scalable capacities for dynamic demands: Our manufacturing reacts agilely to changing customer requirements and efficiently handles complex projects.

Warehouse retrieval in minutes, same-day shipping for orders placed by 12 PM: Thanks to efficient warehousing and logistics processes, even complex components are available and ready for dispatch within the shortest possible time.

Manufacturing in the µ-range with precise adherence to complex form and position tolerances: We ensure the exact implementation of even complex geometric specifications.

Continuously networked processes from 3D model to inspection plan: All production steps are digitally integrated to guarantee quality, efficiency, and traceability.

Competent contacts for quick solutions: Our customers benefit from personal contacts, quick decisions, and solution-oriented communication in real-time.

For over 80 years, HSP has been manufacturing high-precision rolling bearing components. From the growing demand for customer-specific rolling bearing cages, the custom production business unit has developed. Today, HSP is a sought-after technology partner for high-tech industries and innovative manufacturing solutions worldwide. With the brand transition from HSP Schwahlen to HSP Components, we are creating consistent, international communication.