Hybrid Manufacturing

Concept for Complex

Custom Productions

Case Study Plant Engineering

Combined Manufacturing Strategy from 3D Printing, CNC Milling & Surface Finishing

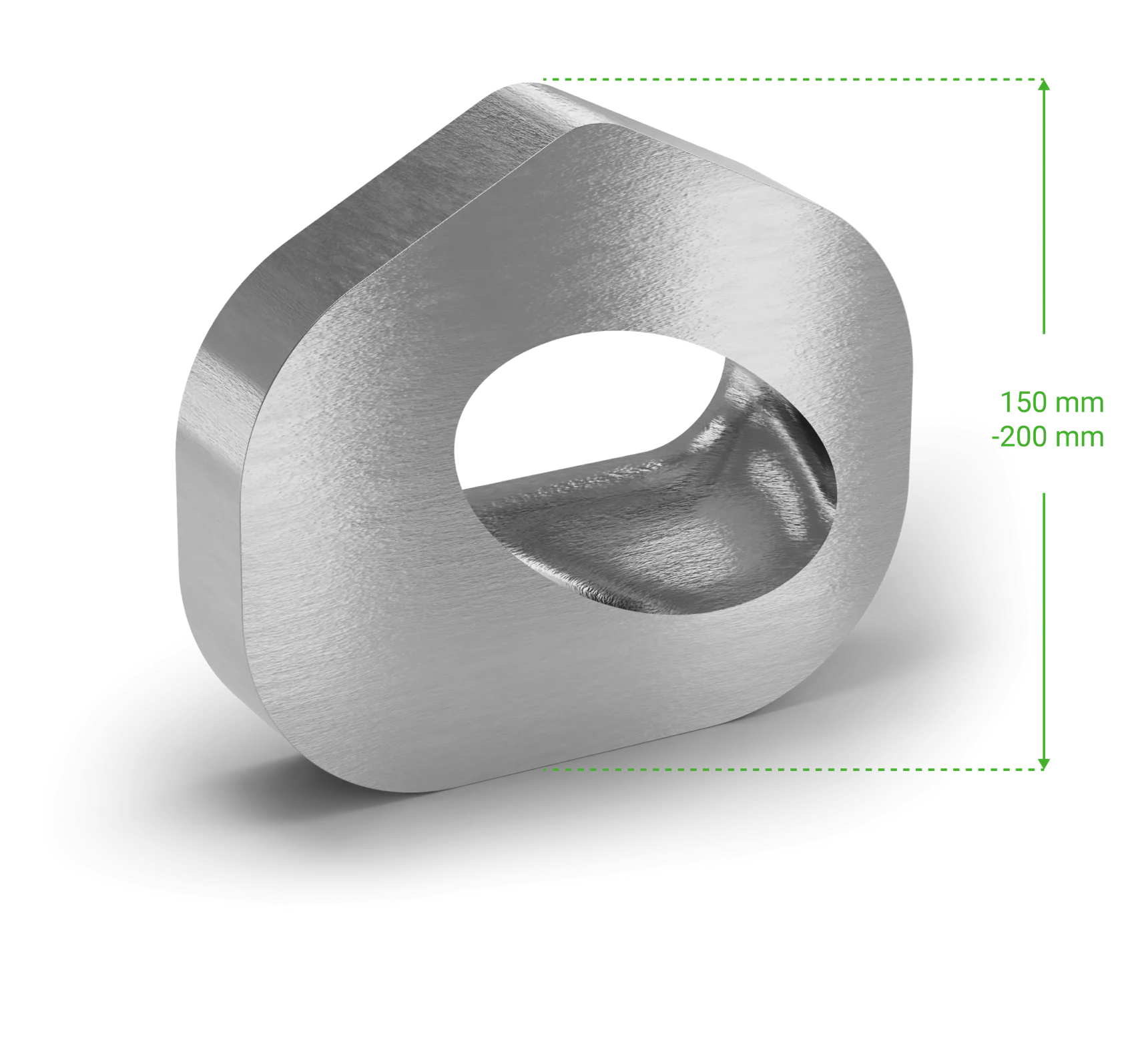

Direct Metal Laser Sintering Part Drawing part

Task: Production of a highly complex stainless steel component for fluid-carrying system modules with a freeform internal structure and the highest requirements for dimensional accuracy, leak-tightness, and series production.

Solution: Hybrid manufacturing concept consisting of 3D printing, CNC machining, and surface finishing, which precisely and economically implements the complex geometry.

Dimension | Material & Hardness | Tolerances & Quality |

|

|

|

Direct Metal Laser Sintering Part Drawing part

Challenge

Overcoming the Limits of Conventional Manufacturing for a Freeform Component Made of Stainless Steel

An internationally operating company in the field of technical plant engineering was seeking a manufacturing partner for the implementation of a high-precision component for flow control and regulation. The custom-designed part – internally also referred to as “Hyd-Muschel” – is used in a fluid-carrying system module, where it performs a central function in the controllable distribution of process fluids. The complex geometry enables optimized flow properties within the smallest possible installation space.

The particular challenge consisted of:

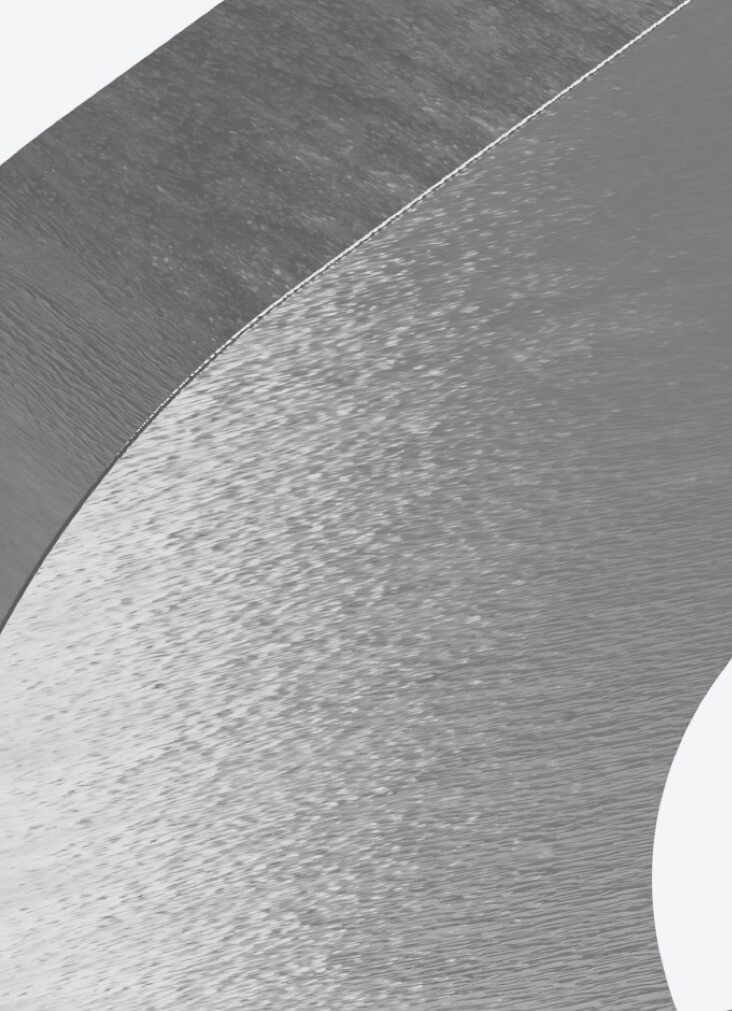

- a freeform, “shell-like” internal structure, which was ideal in terms of fluid dynamics but not conventionally manufacturable

- the processing of high-alloy stainless steel, suitable for fluid-carrying applications

- extremely high requirements for dimensional accuracy, fitting accuracy, and leak-tightness

- the necessity of being able to produce the component economically in series

An internationally operating company in the field of technical plant engineering was seeking a manufacturing partner for the implementation of a high-precision component for flow control and regulation. The custom-designed part – internally also referred to as “Hyd-Muschel” – is used in a fluid-carrying system module, where it performs a central function in the controllable distribution of process fluids. The complex geometry enables optimized flow properties within the smallest possible installation space.

The particular challenge consisted of:

- a freeform, “shell-like” internal structure, which was ideal in terms of fluid dynamics but not conventionally manufacturable

- the processing of high-alloy stainless steel, suitable for fluid-carrying applications

- extremely high requirements for dimensional accuracy, fitting accuracy, and leak-tightness

- the necessity of being able to produce the component economically in series

RESULT

Production-Ready Precision Thanks to Hybrid Manufacturing Solution Made of Stainless Steel

The innovative manufacturing concept made it possible to produce the “Hyd-Muschel” efficiently, with dimensional accuracy, and in series quality. Thanks to the intelligent material-manufacturing mix, the component is now successfully in industrial use and opens up new technological possibilities for the customer in the development of complex plant modules.

What we have done

Innovative Manufacturing Concept for Maximum Precision and Series Production Readiness

HSP developed a customized manufacturing concept for the international plant engineer that precisely realizes the highly complex geometry of the “Hyd-Muschel” and meets the highest requirements for function, dimensional accuracy, and surface quality.

- Additive Manufacturing (3D Printing) from High-Alloy Stainless Steel for Complex Freeform Geometry

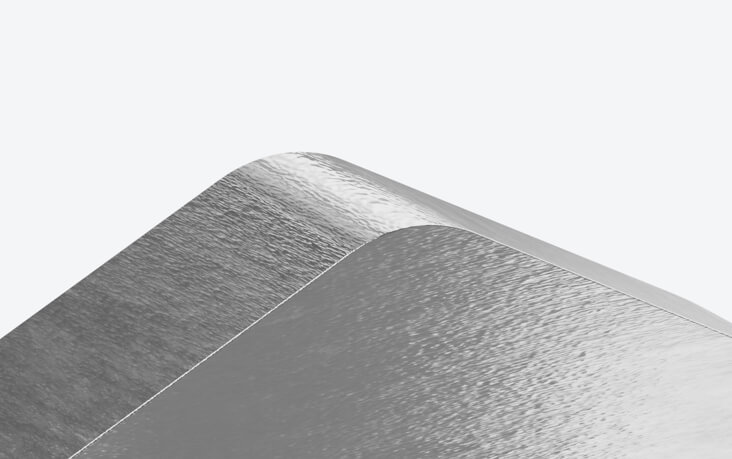

- CNC Milling for High-Precision Functional and Connection Surfaces

- Surface Finishing for Optimizing Flow Quality, Media Resistance, and Leak-Tightness

- Quality Control and Dimensional Inspection

- Process Optimization for Economical Series Production

Today, the hybrid manufacturing concept enables the efficient series production of the “Hyd-Muschel” and provides the customer with new technological possibilities for plant engineering.