Industry solutions and

custom-made products

for the highest demands

Challenges beyond the norm are our daily business. With high-end technologies and decades of experience, we ensure quality

in every dimension.

Individual metal solutions

Custom-made parts for complex and safety-critical applications

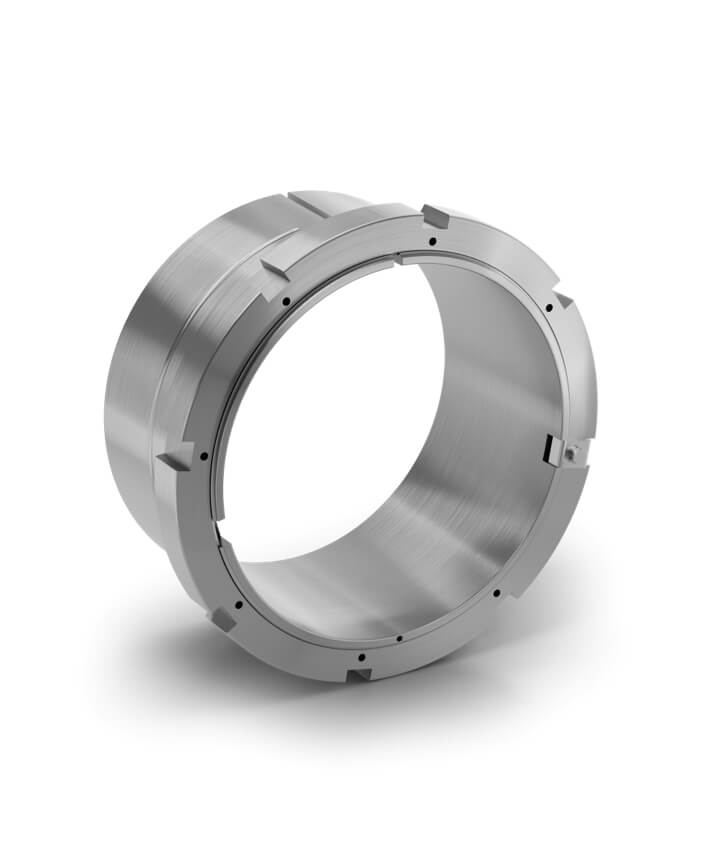

HSP Components develops and manufactures custom-made parts and custom-made products from metal for industries with the highest requirements – from mechanical engineering to energy and drive technology to aerospace. Thanks to our project services for custom-made products and many years of experience in the manufacture of custom-made parts, ready-to-install precision components are created that impress in series production.

Demanding industries

Challenges in tolerances, materials, geometry

Complex geometries and large components with tight tolerances

Components for extreme loads and long service lives

Special components made of

high-performance

materials

Individual documentation and test reports for certified industries

Safety-relevant precision components for critical applications

Fast custom manufacturing for short time-to-market

Whether under high pressure, at extreme temperatures or in delicate precision – many applications place extreme demands on design and manufacturing. Our strength: custom solutions for exactly

these cases – ready to install, precise and reliable. Our customers come from a wide range of industries – they all need precise, ready-to-install parts that make no compromises. High-temperature applications, difficult-to-machine materials or tight tolerances: We know the challenges – and deliver solutions.

How have our customers solved their technical challenges together with us?

Whether under high pressure, at extreme temperatures or in delicate precision – many applications place extreme demands on design and manufacturing. Our strength: custom solutions for exactly

Complex geometries and large components with tight tolerances

Components for extreme loads and long service lives

Special components made of

high-performance

materials

Individual documentation and test reports for certified industries

Safety-relevant precision components for critical applications

Fast custom manufacturing for short time-to-market

these cases – ready to install, precise and reliable. Our customers come from a wide range of industries – they all need precise, ready-to-install parts that make no compromises. High-temperature applications, difficult-to-machine materials or tight tolerances: We know the challenges – and deliver solutions.

How have our customers solved their technical challenges together with us?

Custom-made parts for high-tech industries

Industry solutions for aerospace.

Typical requirements:

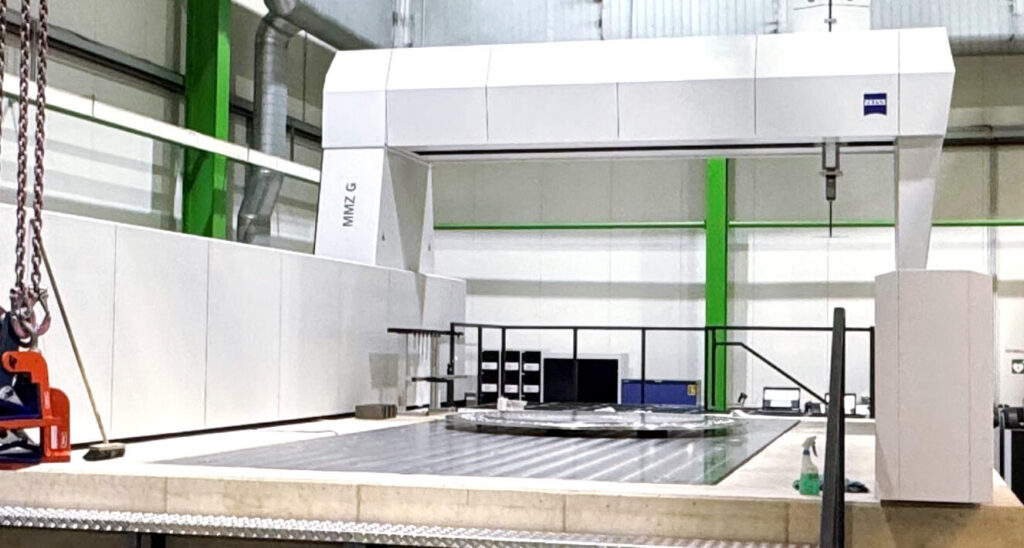

- Precision components in XXL formats and with complex geometries

- Filigree cages with tight tolerances

- High demands on service life and friction minimization

- Secure supply chains for series and spare parts

Our industry solutions:

- Securing and fastening components from our own product range

- Individual rolling bearing cages according to customer drawings – from filigree to large format

- Takeover of complete process chains including heat treatment & hard machining

- Individual logistics solutions for just-in-time or spare parts supply

Selected customer projects:

Typical requirements:

- Components for extreme temperatures and pressures

- Continuous load and long service life in continuous operation

- Special materials and difficult-to-machine materials

- Need for project logistics for large components

Our industry solutions:

- Hydraulic nuts, guide rings and spacers in special materials

- Hard-turned components for extreme operating conditions

- Takeover of complete process chains including documentation and testing

- Project-related logistics solutions for international construction sites

Typical requirements:

- Safety-relevant precision parts with zero-defect tolerance

- Manufacturing from titanium, Inconel and aluminum

- Requirements for heat resistance, corrosion protection and lightweight construction

- Seamless batch tracking and documentation

Our industry solutions:

- Hydraulic nuts, guide rings and spacers in special materials

- Hard-turned components for extreme operating conditions

- Takeover of complete process chains including documentation and testing

- Project-related logistics solutions for international construction sites

Typical requirements:

- Robust, safety-relevant components for extreme operating conditions

- Manufacturing from special materials with high strength

- Requirements for availability and spare parts supply

- Military-specific tests and documentation

Our industry solutions:

- Precision components made of difficult-to-machine high-performance materials

- Complete manufacturing and testing chains including non-destructive testing methods

- Individual logistics and spare parts supply for different application scenarios

- Flexible capacities for series and custom manufacturing

Typical requirements:

- Biocompatible materials with high surface quality

- Precision components for thin-walled, high-precision carrier and receiving rings for rapidly rotating equipment, e.g. magnetic resonance imaging scanners.

- High demands on cleanliness and traceability

- Fast time-to-market for innovations and small series

Our industry solutions:

- Aluminum and stainless steel components in medical technology quality

- Complete process chains including documentation and quality control

- Logistics solutions for small series and on-demand production

- Support with cost-optimized design for manufacturing

Typical requirements:

- Large components with complex geometries and tight tolerances

- Components made of special materials for high loads

- Need for ready-to-assemble modules

- Cost-efficient manufacturing

Our industry solutions:

- Precision components made of difficult-to-machine high-performance materials

- Complete manufacturing and testing chains including non-destructive testing methods

- Individual logistics and spare parts supply for application scenarios

- Flexible capacities for series and custom manufacturing

Selected customer projects:

Why HSP

Mastering complex materials,

stabilizing supply chains

Consistently tested processes and the highest standards ensure certified quality – documentation-safe and reliable for every industry.

Established in the demanding rolling bearing market for decades, we bring deep technological know-how to every customer solution.

As a pioneer of modern manufacturing technologies, we consistently rely on digital processes, transparency and efficient Industry 4.0 solutions.

With specialized manufacturing technology, we realize high-precision solutions for titanium, nickel-based alloys and other special materials.

We manufacture even large-format components with the tightest tolerances – precise, repeatable and in OEM quality.

Thanks to flexible resources and a strong partner network, we can reliably adapt manufacturing capacities to your needs at any time.

Our own logistics center and international partners ensure tailor-made supply chains and on-time delivery worldwide.

We accompany projects from the initial design idea to prototype production and economically scalable series production.

With documentation-safe processes and industry-specific standards, we are a reliable partner in safety-relevant industries.